Article / Case Studies

1Institute of Materials and Construction, Supsi, V. Flora Ruchat 15, CH-6850 Mendrisio, Switzerland.

Christian Paglia

Institute of Materials and Construction

Supsi, V. Flora Ruchat 15

CH-6850 Mendrisio

Switzerland.

26 August 2022 ; 14 September 2022

The road infrastructure is a major concern in the civilization of human being. Roads, bridges and tunnel link people together from the past to the present days. The pavement technology evolved through the centuries. The materials varied with time: from an earthy surface, to stones or cubes, from concrete slabs to hot mix polymer modified drainage asphalt. Depending upon the service condition and the atmospheric exposure, two main materials are used: concrete and asphalt. These building materials exhibited a significant mechanical property evolution in the last decades. Nonetheless, durability aspects, sustainability and maintenance costs awakened some discussions on the general performance of white (concrete) and black (bitumen) materials to be used as a pavement. The case studies focus on some main advantages and disadvantages of both cement-based and bituminous systems. They both can exhibit satisfactory general characteristics, such as surface roughness, mechanical strength, work placing velocity, recycling. Nonetheless, light reflection, surface regularity and the durability may be different. Longitudinal, transverse, net and tongue-like cracks, joints, pop-ups, wash-outs, chemical reactions and surface detachments are some of the defects that influence the functionality. These are largely related to the road layer system properties, road geometry, environment and at the end to the material choice.

Keywords: Concrete, asphalt, road, pavement, durability.

There was a time where the roads were made of stones. Big blocks of materials were placed as a pavement and where supposed to last for a very long time as it was for the city of Pompeii in Naples (Fig. 1 a). In the recent years, some historical city center streets are still made with stones. Granite, gneiss or porphyry cubes or slabs are mainly used due to their load-bearing capacity and mortars are sometimes used to bind them together and at the substrate (Fig. 1 b).

Figure 1: Streets made of stone blocks (a) and slabs (b).

These roads were very durable, but also time consuming in the application by hand. In the meantime the distance covered and the movement of people explored and other materials and methods needed to be applied. Although, the stones remain a main components for today’s roadways. At the present time, two type of materials are used: concrete and asphalt. This latter is widely used, especially for speedways, where the lack of dilatation junctions makes the riding more comfortable.

Nevertheless, concrete roads exhibit a superior durability from 25 to over 50 years as compared to asphalt roads. These latter appear to last for 15-20 years before restoration must take place. This is particularly to observe at the surface level. The deterioration depends on many factors, such as the traffic load condition, the material, the system properties and the environmental issues. In spite of the higher initial costs, on a long-term basis and considering the life cycle analysis, the concrete roads appear to be more convenient (Cement bulletin, 1944; Concrete road pavements, 2009; Zhou et al., 2022). Portland Cement Concrete (PCC) pavements are initially more cost-effective regardless of the cost index value used. But PCC pavements generally exhibit significantly lower maintenance and rehabilitation costs than hot mix asphalt roadways (Embacher & Snyder, 2000). Life cycle analysis also indicates lower environmental pollutions, especially if we take into account the production stage and the health impact during the construction stage for the concrete pavements as compared to the asphalts (Horvath & Hendrickson, 2015). Furthermore, the bitumen used as construction materials instead to produce energy, exhibit a cost lost. Rigid pavements, such as concrete, appear to reduce the fuel consumption because of the less resistance of the rolling tyres as compared to asphalt pavements.

The load distribution on a rigid pavement is more widespread on the surface and less intense locally as for a flexible asphalt road. Moreover, less thermal impact and major heat and light reflection may be accounted for. Stone aggregates exposition may better reduce the noise of the rolling tyres as compared to the noise adsorbent asphalt, which porosity is often filled with material, thus reducing the noise reduction effect on the long-therm. Volatile organic carbon compounds are also a concern in asphalt pavements. In case of fire, particularly in tunnels, the concrete exhibits a better behaviour as compared to asphalt. This latter exhales toxic gases and promotes the combustion with an exothermic reaction that reduces the mechanical properties of the pavement.

On the other hand, the lack of frequent junctions along the asphalt pavements and the technological improvements make them appropriate to be used along highways and in most of the streets worldwide. And yet, asphalts can be placed more quickly than concrete and they provide a slightly better safety of the vehicle against snow and skidding. A five years study on a similar length of a 3.5 km long Portland Cement Concrete Pavement (PCCP) and an adjoining Asphalt Concrete Pavement (ACP) along the Trans-Canada highway exhibited a similar well performance after five Winters. The PCCP indicated a better profile ride and riding comfort index as well as friction values. The ACP section exhibited slightly lower roadside noise levels (Smith, 1994).

The scope of this work is to outline the main concerns in the application of bituminous and cementitious materials as a roadway pavement by means of some case studies analyzed with time. Aside from the main material properties, such as the compaction degree, the rutting resistance, the binder type, the load bearing capacity of the system and the long-term detrimental reactions, the resistance against shear stresses and the general durability of the surface are crucial topics. Consequently, they need to be carefully considered in order to have a long lasting infrastructure.

Visual inspection, thermographic analysis and the main characterization aspects of the durability (Swiss standard SIA 262, 2013; Swiss standard SIA 262/1, 2013; Standard SN EN 206-1, 2000) were applied. The observations were done on infrastructures placed in different geographical areas from 200 to 2470 meters above sea level. Several type of structures, such as conventional streets, highways, mountain roads, roundabouts and bus stops were investigated. These structures are subjected to different type of solicitations, that control the durability of the road building system.

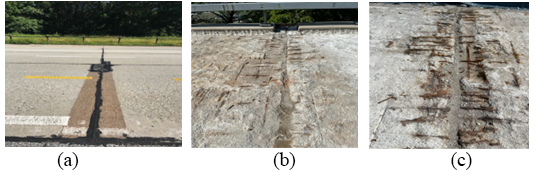

Concrete roads are built with slabs of different size and thickness. These latter depend of the traffic frequency and type. Some concrete slabs are reinforced with steel rebars to resist the tension. Prior to the II World War steel round rebars were used in concrete slabs. During the War the steel consumption focused on the conflict. Consequently, welded steel nets were used. The nets are particularly present in old concrete slabs placed 50 years ago. Junctions are often necessary because of the thermal dilatation. The junctions are placed longitudinally and transverse to the traffic direction (Fig. 2 a). Sometimes the slabs move with respect to one another. In fact, the junctions durability is adversely affected by the penetrating water that interacts with the unbinded ground underneath. This causes leaching and vertical slabs movements. In addition, the water infiltration may have a detrimental effect on the underlying nets and steel rebars, thus causing corrosion (Fig. 2 b, c).

Figure 2: Junctions and rebar corrosion on a 40 cm wide junction zone after 50 years.

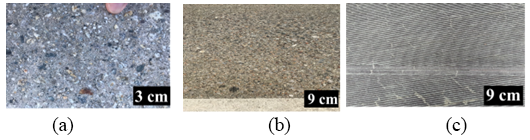

In spite of the fact that the concrete roads may still be in an acceptable condition after many decades (Paglia & Mosca, 2023), damage can be observed in many slabs. Water leaching causes the surface stone aggregate exposure (Fig. 3 a). The concrete texture on street border often becomes more clearly visible (Fig. 3 b). This is caused by the water leaching and enrichment along the artificial slope as well as the water drainage from the road centre to the sides. However, the roughness and tyre adhesion is maintained. If it is not the case, surface rifling and striations are artificially applied to attain the necessary surface roughness (Fig. 3 c).

Figure 3: Surface leaching and roughness of concrete pavement slabs.

Figure 3: Surface leaching and roughness of concrete pavement slabs.

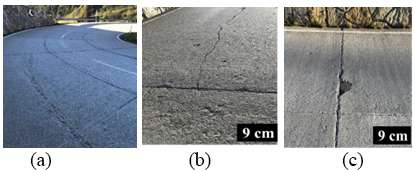

Cracking is a main deterioration issue that takes place within the slabs. Cracks are caused by load, fatigue, shrinkage, chemical and environmental actions. Beyond the longitudinal cracks along some slabs, the road curves exhibit additional crack deterioration zones due to the surface shear stresses (Fig. 4 a). Longitudinal cracks generally propagate across the slabs from joint to joint (Fig. 4 b). Tongue-like fracture along junctions are often due to the freezing action and this form of degradation was especially seen in the altitude above 2000 meters above sea level (Fig. 4 c).

Figure 4: Cracking of concrete slabs on a 50 years old roadway located above 2000 meters above sea level.

Figure 4: Cracking of concrete slabs on a 50 years old roadway located above 2000 meters above sea level.

An important issue that needs to be carefully addressed is the restoration of such structures. The most deteriorated slabs are demolished and replaced by new concrete added with a steel rebar net (Fig. 5). The new material may be a compressive strength class C 30/37 concrete with environmental exposition classes XC4, XD3, XF4. They indicate a relative high durability against corrosion induced by carbonation, by chlorides and exhibit a good freeze / thaw resistance. The strength reached by the pavement slabs is 56.7 +/-6.9 N / mm2. The freeze / thaw cycles resistance in the presence of deicing salts ranged from 20 g/m2 to 1200 g/m2. The chloride migration coefficient varied from 9.2 to 18.9*10-12 and the water permeability coefficient ranged from 4.8 to 7.1 g/m2h. Not in all cases the requirements are achieved, although a sufficient durability is attained. This also depends on the environment and functionality of the roadway. Nonetheless, it exists a trend to overlay with asphalt the old, restored or replaced concrete slabs.

In this concern, in order to avoid reflection cracking of the asphalt cover top down along the underlying concrete joint slabs, it is necessary to introduce asphalt joints or to apply a sufficient asphalt overlay thickness of minimum 200 mm. The thickness depends on the cracking content and conservation state of the underlying concrete slabs.

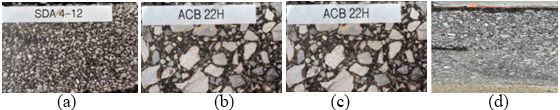

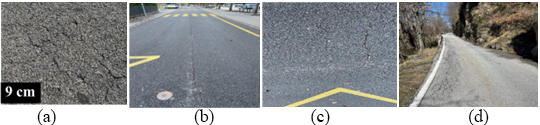

The asphalt is a more flexible material as compared to concrete and the load is less widely distributed through the surface. Therefore, the loading is more concentrated on a narrow space and the durability may suffer. For this reason, the placing mainly occurs in layers, with the lower bituminous binded and unbinded layers acting as a load carrying material. Conventional roads usually exhibit three layer systems, while high speed highway may show four layers of asphalt. The type of materials mainly depend on traffic load and frequency in order to better distribute the load. The binder type, polymer addition and the aggregate size are also considered. The typical stratigraphy from the top to the bottom may consist of a surface layer followed by a binding and a base layer and an unbinded compacted foundation layer. Usually the surface layers may exhibit smaller maximum aggregate size ranging from 4 to 12 mm and mastic asphalt type (Fig. 6 a). The addition of polymers or fibres may help against abrasion or rutting. The lower layer aggregate size may vary from 16 mm to 22 for the base and binding course (Fig. 6 b) up to 45 mm and over for the unbinded foundation layer (Fig. 6 c). The compaction degree may vary with time. More cavities and macro voids are present on the surface regions, while a higher compaction is generally seen with time. In this case, a dense macrostructure is observed after 15 years along a highway pavement stratigraphy. Although, occasionally porosity is seen along the layer interfaces (Fig. 6 d).

Figure 6: Possible asphalt type (picts Comibit SA), unbinded foundation aggregates and macropores along a highway pavement system.

Figure 6: Possible asphalt type (picts Comibit SA), unbinded foundation aggregates and macropores along a highway pavement system.

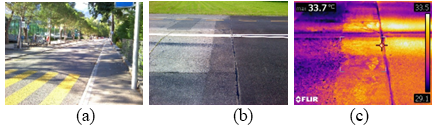

The concrete pavements generally exhibit a higher durability, while they are subjected to the main degradation mechanism as conventional concrete, such as freeze scaling, leaching, aggregate pull-out, chemical reactions, in particular the alkali-silica expansive reaction on a long-term basis. On the other hand, the main issues for asphalt are the age hardening and the oxidation of the bituminous binder in the warm paving phase and with time. Volatile components of the Maltene go into the air and the more rigid Asphaltene component remains left. These processes make the bitumen more rigid and increase the susceptibility to cracks. The bituminous material exhibits visco-elastic properties, which are more dependent on the temperature as compared to concrete. Cracks form along the hydrophobic bitumen layer, while in concrete mainly along the cement and cement-aggregate interface. Both materials are subjected to daily and seasonal temperature excursions that create differential tensions within the material. Also during a single moment of the day, the temperature and shadow distribution along a roadway may vary in short distance (Fig. 7 a), thus enhancing the different thermal solicitation of the material. In addition, the temperature measured in a summer evening along a junction concrete-asphalt pavement, remains higher for a longer time on the asphalt surface, also due to its black color (Fig. 7 b, c).

Figure 7: Temperature distribution on an asphalt pavement during a summer evening in July in a moderate continental clima.

Figure 7: Temperature distribution on an asphalt pavement during a summer evening in July in a moderate continental clima.

The binder content range from 2-6 % by weight in asphalts and reaches 15 % in concrete. In this latter material the binder continues the hydration with time with a relative positive effect, by surrounding the aggregates with an amorphous gel, thus developing an adhesion strength. The strength levels off depending on the hydration and the formation of cracks due to conventional concrete degradation phenomena with time. On the other side, the entrance of aggressive agents, such as CO2 and chlorides play a relevant role for the corrosion of steel net or rebar if present.

Apart from the sensitivity to environmental factors of the binders, the durability in concrete and particularly in asphalts is largely influenced by the pavement system as a whole, the placing and the service condition, in particular fatigue loads. In addition, the temperature, moisture, drainage, weather, compaction, segregation, joints, layer bond, aggregate properties, gradation and volume also play a relevant role.

Surface degradation appears through thermal cracks, especially in altitude and low temperature (Fig. 8 a), geometric effects, or along slopes on both side towards the street edges. This latter geometry may create longitudinal cracks in the middle due to the load tension caused by the traffic (Fig. 8 b). Consequently, a crack pattern system arises also with transversal cracks starting from the longitudinal ones (Fig. 8 c). The unbinded ground material also play a significant role in the pavement system duration. The lithology, granulometry, form of the aggregate as well as the compaction of the foundation layer (> 80-100 MN) are important to get a durable asphalt pavement. The fine particle content is often related with freezing issues, while a too high content does not allow to reach the required compaction degree, in spite of the multiple compaction roller steps. Any ground subsidence raised from load, water leaching effects, inadequate gradation of the rock aggregates, lithology and freeze / thaw effects promote cracks formation or deformation of the surface asphalt courses with a partial detachment of the upper layers as it may be along the road side towards the mountain slope (Fig. 8 d).

Figure 8: Some deterioration type of asphalt surfaces.

Figure 8: Some deterioration type of asphalt surfaces.

The durability of asphalt pavements may be prolonged by increasing the binder content. This appears to improve the resistance to ageing, moisture damage and cracking. The use of polymers, fine gradation mixtures and an adequate mix design reduce the air voids and increase the water impermeability (Bonaquist, 2014). Tack coats, which consists of an asphalt emulsions diluted with water, are also applied to improve the layer bond strength. During this procedure, the application rate, the wetness and the preparation of the surface need to be carefully controlled (Mohammad & Elseifi, 2014). The fatigue, the techniques and the standardization to measure it (Hofko, 2022), as well as high modulus asphalts (Botes, 2016), also improve the resistance of the pavements. To maximize the durability aspects, several operations can be done, such as limiting the number of joints and an adequate sealing of them, a good compaction and the water control by avoiding or limiting the permanence on the structures (Nicholls et al., 2008). Ultraviolet exposition is also a mechanism of bitumen ageing that needs to be taken into account (Li et al., 2022). In spite of the constant experience gathered in the use of cold and warm asphalt mixtures, their durability still appears significantly lower as for hot asphalt mixes.

Self-healing of concrete and asphalts are a main concern. It may take place naturally with rest periods (Baaj et al., 2002), or artificially through the use of special techniques or materials (Quantao et al., 2010). Both bituminous and cement-based materials are largely investigated with respect to the self-healing properties with microwave heating (Gallego et al., 2013), induction (Garcia, 2008), fibre addition (Schlangen & Sangadji, 2013), bacteria (Jonkers & Schlangen, 2008) and microcapsules (Al-Mansoori et al., 2017; Li et al., 2015). Nevertheless, in the case of a progression and enlargement of cracks due to the permanent solicitation of the structures, some methods may be currently limited in the efficacy.

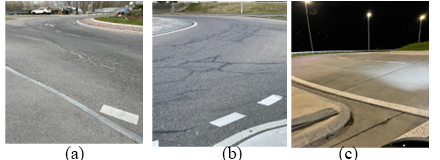

The roundabouts increased the presence along roadways in the last decades. They were thought to optimize the traffic flow and to get right of some stop lights. They are useful when streets exhibit a similar traffic load. On the contrary, they adversely affect the fluidity when the roads show a significantly different traffic frequency. In these structures high shear stresses are present. Therefore, inadequate asphalt mixtures are unable to width stand the tensions and the cracks that mainly form along the traffic direction (Fig. 9 a) and propagate on all sides (Fig. 9 b). In some cases, vehicles tracks and rutting are seen. This latter is caused by the material deformation. In highly busy roundabouts, the pavement is replaced with jointed concrete slabs to increase the durability (Fig. 9 c).

Figure 9: Degradation and pavement type of roundabouts.

Figure 9: Degradation and pavement type of roundabouts.

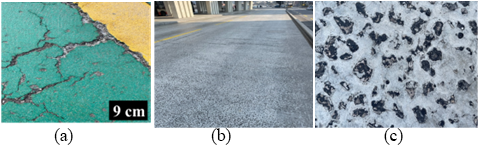

The bus stops are also exposed to intense shear stresses. Stops and departures of buses create tensions along the pavements and accelerate the formation of cracks (Fig. 10 a). Where shear stresses are frequent during daily service and regardless of the possibility to switch to a more rigid polymer modified bituminous binder, a combination of asphalt and cementitious material allow the obtain more rigid pavements (Fig. 10 b, c). The top layer of these pavements are made of open void asphalts, such as water drainage asphalts, with addition of cementitious material that fills the open spaces. The presence of the cementitious filler may not always be homogeneous through the surface. Furthermore, this surface treatment remains questionable with respect to the durability of the whole top layer system.

Figure 10: Asphalt and asphalt-cement-based pavements along bus stops.

Figure 10: Asphalt and asphalt-cement-based pavements along bus stops.

The mechanical properties of these asphalt surface layers filled with cement-based material exhibit an interesting performance and rigidity. Nevertheless, durability issues, such as for instance the resistance to freeze / thaw cycles still needs to be clarified. The bond strength between the aggregate surrounded by a bituminous layer and the cement matrix may suffer from the thermal dimensional variation on a long-term basis. Therefore, the pavements might be placed only in special geographical areas with moderate clima.

The recycling is a major concern in the pavement sector, where a high amount of waste material is produced during the restoration and replacing works. Therefore, it is necessary to further clarify the use of alternative materials and recycled aggregates.

Recycled concrete aggregates can be added up to 50 % with respect to the total aggregate weight to obtain durable concrete with reasonable mechanical properties. This can be attained if the origin and the homogeneity of the demolition material are known (Paglia et al., 2022; Paglia et al., 2022). Naturally, the quality of the recycled aggregates needs to be kept under control and improved with a reduction of the porosity. New binders and superplasticizers mix proportion have to be set correctly in order to use the appropriate addition of recycled aggregate depending on the load and traffic capability of the roadway. Possible ongoing alkali-silica reactions (Paglia & Mosca, 2023) and potentially reactive aggregates have to be identified. On the other hand, chloride contaminations must be detected, if the material is used in the presence of steel rebars. The recycled material can also be used for low grade valorization purpose, such as unbinded foundation layer.

Reclaimed Asphalt Pavements (RAP) aggregates are widely present. They are utilized as unbinded foundation layers or as a component of new asphalt mixtures. In this latter case, the performance based characteristics as well as the compactability of the mixtures, the aggregate features, the packing, the surface treatments, mechanical and durability aspects need to be clearly identified. In particular, the old stiff binders around the aggregates and the resulting increased rigidity of the reclaimed materials (Bonaquist, 2016) needs to be counterbalanced by the use of softer binders or rejuvenators. In fact, cluster phenomena as well as adherence of RAP particles to virgin aggregates and the re-activation degree of the old binder need to be considered to optimize the mix design of asphalt pavements added with reclaimed asphalt material (Bressi, 2016). Aside from the RAP aggregates and the recycling agents added to restore the old binder properties, crumb rubber and plastics may also be used as an addition to the hot mixtures (Hameed, 2021). In spite of the fact that RAP increase the stiffness and may have a beneficial effect of the rutting resistance at high temperature, the thermal and fatigue cracking behaviour remains partially unclear. In some cases, the addition to a maximum of 20 % by weight may ease the mix design (Al Dughaishi et al., 2022). Sometimes the use of roadways reclaimed asphalt is not allowed for the top layer of highways, while for the lower courses an addition up to 50 % is permitted. The contaminants content, such as the poly aromatic carbon hydrates, the heavy metal leaching (Rahmad et al., 2022) and content also need to be controlled. In this regard, an environmental life cycle analysis considering the RAP mixtures showed an increase in the score in the environmental indicators. The addition of crumb rubber adversely affected the environmental parameters (Bressi et al., 2019).Nevertheless, the pollutants agents must be controlled on the concrete material as well, prior to recycling. Both asphalt and cementitious materials can be mixed during a recycling phase, such as for the full-depth reclamation of pavements with Portland cement, to re-use old asphalt pavements (Fedrigo et al., 2020). Nevertheless, this is a topic that needs to be further widely investigated.

Concrete and asphalt exhibit a similar basic material features of a system with a binder and rock aggregates. Nonetheless, the characteristics of the bituminous binder of the asphalts is completely different from cements. Its thermal susceptibility and visco-elastic properties have a strong influence on the pavement system. A layered system is applied for the more soft asphalts and a single layer for the more rigid concrete. Adequate adjustments of the binders, i. e. cement or bitumen, aggregates, construction features, placing strategies as well as the unbinded soil compaction make both systems applicable in most cases. Although the absence of frequent junctions makes asphalt widely used.

On the other hand, the durability appears to be generally higher for concrete pavements, in particular where high shear stresses resistance are required. Typically on roundabouts and bus stops. Both materials seem to be recycled to a significant extent with the adequate mix proportion, but not higher than 50 % by weight. A mixed alternative of the two materials concrete and asphalt or technological improvements in order to increase the rigidity and the durability of the pavements without or less junctions must be deeply evaluated. This will allow to get more durable roadways and less frequent repair works along the today and future heavily trafficked roadways.

The authors would like to thank the technicians of the Institute of materials and construction for sample preparation and testing.

- Cement bulletin. (1944). TFB, The concrete road during and after the war, N. 10, October, Switzerland.

- Concrete road pavements. (2009). Italian technical-economical association of cement industry, Aitec.

- Zhou, X., Zhang, X., Zhang, Y., & Adhikari, S. (2022). Life cycle assessment of asphalt and cement pavements: Comparative cases in Shanxi Province, Construction and Building Materials, 315(10). https://www.sciencedirect.com/science/article/abs/pii/S0950061821034723

- Embacher, R. A., & Snyder, M. B. (2000). A Comparison of life-cycle costs of asphalt concrete and Portland cement concrete. Final report to Concrete paving association of Minnesota. University of Minnesota.

- Horvath, A. & Hendrickson, C. (2015). Comparison of environmental implications of asphalt and steel-reinforced concrete pavements. Transportation research record 1626 Paper No. 98-0661. Retrieved from https://trid.trb.org/view/540297

- Smith, T. J. (1994). Results of highway 104 Nova Scotia, 5-yr study comparing performance of adjoining asphalt and concrete pavements. Transportation and Public Works, Cement Association of Canada.

- Swiss standard SIA 262, Concrete construction, 2013.

- Swiss standard SIA 262/1, Concrete construction – complimentary directives, 2013.

- Standard SN EN 206-1. (2000). Concrete – part 1: Specification, quality production, conformity. Retrieved from chrome-extension://efaidnbmnnnibpcajpcglclefindmkaj/https://allbeton.ru/upload/iblock/d27/bs_en_206_1_2000_concrete_part_1_specification_performance_production_and_conformity.pdf

- Paglia, C. & Mosca, C. (25-29 June 2023). The concrete road pavement durability: a study of over 50 years old concrete structures in a South alpine space, The 14th International Symposium on Concrete Roads – Krakow, Poland. Retrieved from https://www.eupave.eu/events/14th-international-symposium-on-concrete-roads/

- Bonaquist, R. (2014). Impact of mix design on asphalt pavement durability. Workshop enhancing the durability of asphalt pavements. Transportation Research Board of the National Academies, Washington, USA. Retrieved from https://trid.trb.org/view/1326307

- Mohammad, L. N. & Elseifi, M. A. (2014). Optimization of tack coat for hot-mix asphalt placement. Workshop enhancing the durability of asphalt pavements, Transportation Research Board of the National Academies, Washington, USA. Retrieved from https://trid.trb.org/View/1326309

- Hofko, B. (2022). M&S highlight: Di Benedetto et al. (2004), Fatigue of bituminous mixtures. Materials and Structures, 55, 34. Retrieved from https://link.springer.com/article/10.1617/s11527-021-01856-x

- Botes, H. B. (2016). Characterization of high modulus asphalt (EME) mixes, focusing on flexural response and fatigue. Retrieved from chrome-extension://efaidnbmnnnibpcajpcglclefindmkaj/https://core.ac.uk/download/pdf/188224029.pdf

- Nicholls, J. C., McHale, M. J. & Griffiths, R. D. (2008). Best practice guide for durability of asphalt pavements. Transportation Research Laboratory, Publisher HIS, UK. Retrieved from https://trl.co.uk/publications/rn42

- Li, Y., Feng, J., Chen, A., Wu, S., Bai, T., Liu, Q. & Zhu, H. (2022). Development mechanism of aging depth of bitumen with increasing UV aging time. Case Studies in Construction Materials, 17. Retrieved from https://trid.trb.org/view/1940097

- Baaj, H., Benedetto, H. D. & Chaverot, P. (2002). Fatigue of mixes: an intrinsic damage approach. The 6th International Rilem Symposium on performance testing and evaluation of bituminous materials. Retrieved from https://www.rilem.net/publication/publication/33

- Quantao L, E. Schlangen, M. van de Ven and A. Garcia, (2010). Healing of porous asphalt concrete via induction heating, Road Materials and pavement design, 11, 527-542. DOI: http://dx.doi.org/10.1080/14680629.2010.9690345

- Gallego, J., del Val, M. A., Contreras, V. & A. Paez. (2013). Heating asphalt mixtures with microwaves to promote self-healing. Construction and building materials, 42. DOI: https://doi.org/10.1016/j.conbuildmat.2012.12.007

- Garcia, A., Schlangen, E. & van de Ven, M. (2008). Two ways of closing cracks on asphalt concrete pavements: microcapsules and induction heating. Key Engineering Materials, 417. DOI: http://dx.doi.org/10.4028/www.scientific.net/KEM.417-418.573

- Schlangen, E. & Sangadji, S. (2013). Addressing infrastructure durability and sustainability by self-healing mechanisms – Recent advances in self-healing concrete and asphalt. Procedia Engineering, 54, 39-57. DOI: https://doi.org/10.1016/j.proeng.2013.03.005

- Jonkers H. M. & Schlangen, E. (2008). A two component bacteria-based self-heling concrete. DOI: http://dx.doi.org/10.1201/9781439828403.ch27

- Al-Mansoori, T., Micaelo, R., Artamendi, I., Norambuena-Contreras, J. & Garcia, A. (2017). Microcapsules for self-healing of asphalt mixture without compromising mechanical performance. Construction and Building Materials, 155, 1091-1100. DOI: http://dx.doi.org/10.1016/j.conbuildmat.2017.08.137

- Li, R., Zhou, T. & Pei, J. (2015). Design, preparation and properties of microcapsules containing rejuvenator for asphalt, Construction and Building Materials, 99, 143-149. DOI: http://dx.doi.org/10.1016/j.conbuildmat.2015.09.017

- Paglia, C., Paderi, M., Mosca, C. & Antonietti, S. (2022). The recycling of a concrete with known properties to reproduce a durable material for the civil engineering infrastructure, International meet on civil, structural and environmental engineering, 23-26 Mai, Munich, Germany, online, Civilmeet. Retrieved from chrome-extension://efaidnbmnnnibpcajpcglclefindmkaj/https://www.albedomeetings.com/cms/pdfs/CIVILMEET2022-tentative-program.pdf

- Paglia, C., Antonietti, S. & Mosca, C. (2022). Known properties of concrete to produce high quality recycled cementitious material for buildings. The 15th International Conference on Recent Advances in Concrete Technology and Sustainability Issues, July 13-15, Milan, Italy. Retrieved from chrome-extension://efaidnbmnnnibpcajpcglclefindmkaj/https://www.aciitaly.com/wp-content/uploads/2022/07/SOCAC-RACTSI-CIRCULAR-XIV-FINAL-PROGRAM.pdf

- Bonaquist, R. (2016). Critical factors affecting asphalt concrete durability. Wisconsin highway research program. Retrieved from https://rosap.ntl.bts.gov/view/dot/37679

- Bressi, S. (2016). Advanced methodology for optimization of mixture design of asphalt concrete containing reclaimed asphalt pavement material. Swiss Federal Institute of Technology, EPFL, Thesis No 6913, Lausanne, EPFL. https://infoscience.epfl.ch/record/217900?ln=en

- Hameed, I. (2021). A review of RAP and its use in pavement engineering. Global Journal of Engineering and Technology Advances, 7(1), 073–084. DOI: https://doi.org/10.30574/gjeta.2021.7.1.0043

- Al Dughaishi H., Lawati, J. Al., Bilema, M., Babalghaith, A. M., Mashaan, N. S., Yusoff N. I. M. & Milad, A. (2022). Encouraging sustainable use of RAP materials for pavement construction in Oman: A Review. MDPI, Recycling, 7(3), 35. DOI: https://doi.org/10.3390/recycling7030035

- Rahmad, S., Khahro, S. H., Rosyidi, S. A. P., Widyatmoko, I., Memon, N. A., Al-Sabaeei, A. M., Milad, A., Sutanto, M. H. & Yusoff, N. I. Md. (2022). Assessment of metal leaching from rediset-polymer modified asphalt binder on groundwater and soil contamination. Case Studies in Construction Materials, 16. DOI: https://doi.org/10.1016/j.cscm.2022.e01108

- Bressi, S., Santos, J., Marko O. & Losa, M. (2019). A comparative environmental impact analysis of asphalt mixtures containing crumb rubber and reclaimed asphalt pavement using life cycle assessment. International Journal of Pavement Engineering ,22(4). DOI: https://doi.org/10.1080/10298436.2019.1623404

- Fedrigo, W., Peres Núñez, W. & Visser, A. P. (2020). A review of full-depth reclamation of pavements with Portland cement: Brazil and abroad. Construction and Building Materials, 262(3), 120540. DOI: http://dx.doi.org/10.1016/j.conbuildmat.2020.120540